Four press lines are equipped with 24 sets press machine ranging from 63t to 2000t. Joylong invests 600 million to buy more than two thousand sets of mould, fixture for the needs of the entire vehicle stamping parts, through accurate adjustment, to achieve the appearance quality of the stampings and hole location precision of zero error.

We adopt the advanced welding process of welding workshop, and body assembly welding lines are completed by the German import KUKA robot. The operation error is less than 1mm, because we keep improving to create the body and the mathematical model of completely consistent.

Closed dust free painting workshop is equipped automatic production line with the vehicle body pretreatment, parkerising, cathode electrophoresis primer. Floating coat, top coat are completed by imported automatic robot, precision processing, so as to ensure the perfect full body paint.

Assembly workshop according to the models are divided into department one, two, three. The production line adopts fully automatic assembly line, according to the modular assembly form, on the basis of Toyota advanced production mode to organize production. There are advanced vehicle performance testing lines, and the United States Bee-Line, four wheel positioning and other advanced equipment to ensure that the assembly without defect.

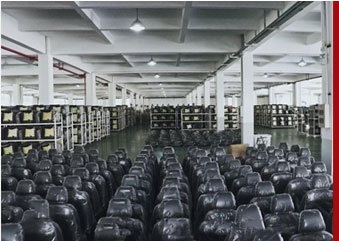

In the control of the vehicle accessories, Joylong has its own components supporting enterprise- Hongye Auto Parts of nearly 20 years of manufacturing experience. Its products cover the whole car accessories to realize a complete set of controllable, and the quality is more reliable.

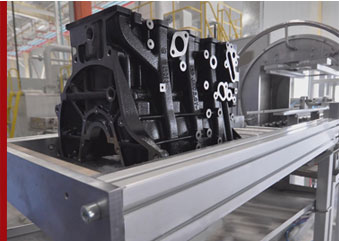

On the control of the core engine, through cooperation with well-known automobile research institute, Joylong sets up its own engine manufacturer, and opens up the whole industry chain, becoming a real vehicle manufacturing enterprise, a leading in the peer manufacturing enterprise.